Case Study: Next-Generation HaWK Solar Arrays

MMA HaWK Solar arrays

Players: MMA Design

The Challenge

MMA has been a leader in providing space power for CubeSat missions for over a decade. While MMA’s solar arrays tailored to small spacecraft have led the industry in power, packaging efficiency, customization, scalability, and configurations, our solutions have not always been attainable for all missions.

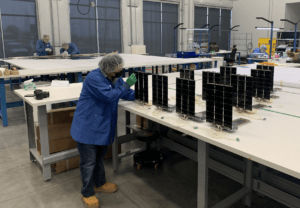

SunRISE HaWK Solar Arrays prepare for shipment.

Convinced that superior performance can benefit a broader audience more cost effectively and without sacrificing quality, MMA is introducing a battery of data-informed improvements and innovations that will once again revolutionize space power for SmallSats and beyond.

eHaWK Solar Arrays during final inspection at MMA.

The Solution

The advantages of MMA’s High Watts per Kilogram “HaWK” solar arrays for CubeSats are clear: innovative packaging and restraint schemes, highly modular architectures, fully customizable designs, and best-in-class performance metrics. So where do you go when you are already at the top of your space power game?

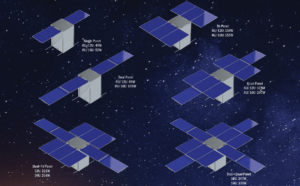

MMA’s next-generation HaWKs are optimized for use on all four walls of a 12U/16U spacecraft or opposite faces of a 6U/8U spacecraft, to maximize power density. MMA’s proprietary, custom cell sizes are optimized for canister-deployed satellites, boosting power output by 50% in the same available stowed envelope as our previous arrays.

Next-generation HaWKs optimized for canister- deployed satellites.

Other incremental improvements lower the parts count, hence the labor involved in manufacturing, assembly and integration. In-house welding of cell strings and assemblies reduces cost and schedule while providing improved reliability and longer life over soldered assemblies. Flexible circuits reduce cost and schedule by simplifying panel wiring design and installation.

Additionally, consider critical, integrated new features like peak power tracking or a low-profile SADA with a built-in controller.

The Results

- 50% more power for CubeSats in the same available envelope.

- Lower cost and higher reliability through flexible circuits and welded assemblies.

- Scalable from cubesats to kilowatt+ ESPA SmallSats.

- Quicker, easier and more affordable to manufacture, assemble, test and integrate on your spacecraft.

Applying our unique brand of innovation to customizable HaWKs means we will once again disrupt a market where space power has become a commodity.

Lunar Outpost Rover’s custom deployable solar arrays wings.

Check out our table of existing HaWK configurations, or contact our product specialists for your custom solar array needs.